Mastering Auto Frame Repair: Shop Selection Guide for Quality Results

Auto frame repair is a specialized service for restoring vehicle structural integrity post-accident……..

Auto frame repair is a specialized process within the automotive industry, focusing on restoring structural integrity to a vehicle’s body frame. This intricate art involves skilled technicians meticulously mending bent or damaged metal components, ensuring safety, aesthetics, and the longevity of vehicles. In an era where vehicle design and manufacturing have evolved exponentially, understanding auto frame repair becomes increasingly vital for both consumers and industry professionals. This article aims to delve into the intricacies of this trade, explore its global impact, and shed light on the challenges, innovations, and future prospects that shape its development.

Auto frame repair is a complex process that involves the following key components:

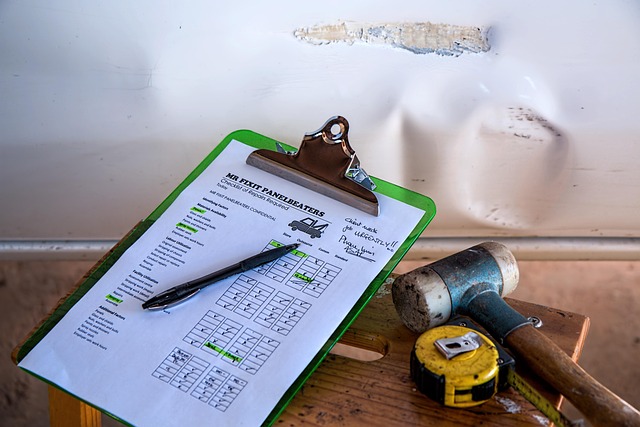

Assessment and Analysis: The journey begins with a thorough inspection of the vehicle’s body frame, identifying damage patterns, severity, and potential structural weaknesses. Advanced diagnostic tools are employed to pinpoint issues accurately.

Metal Repair Techniques: Skilled technicians utilize various methods such as welding, riveting, and specialized metal forming techniques to straighten and reinforce damaged panels. Modern equipment ensures precision and minimal distortion.

Structural Integrity Restoration: The primary goal is to restore the frame’s structural stability, ensuring the vehicle’s safety during operation. This meticulous process involves realigning components, replacing worn-out parts, and utilizing advanced engineering principles.

Historically, auto frame repair evolved alongside advancements in automotive manufacturing. As vehicles became more complex, with intricate designs and lightweight materials, the need for specialized frame repairs grew. Over time, this trade has honed its techniques, embracing technological innovations to enhance precision and efficiency. Today, it stands as a critical component of vehicle maintenance, ensuring both safety and aesthetics.

The influence of auto frame repair extends far beyond national borders, with significant global implications:

International Market Dynamics: The global auto repair industry, including frame repair services, is valued at over $1 trillion, showcasing its immense scale. Regions like North America, Europe, and Asia-Pacific dominate, with each having unique market characteristics.

Regional Disparities: Developing countries often face challenges in accessing advanced frame repair technologies due to infrastructure gaps and limited access to specialized training. This disparity highlights the need for tailored solutions and capacity building.

Emerging Markets Growth: Countries like India and Brazil are witnessing rapid expansion in auto frame repair services, driven by increasing vehicle ownership and a growing middle class. This trend presents significant opportunities for global providers.

Global trends shaping this sector include:

| Trend | Description |

|---|---|

| Advanced Materials | The adoption of lightweight materials like aluminum and composites is driving innovation in frame repair techniques to preserve structural integrity while reducing weight. |

| Digitalization | Digital technologies, including 3D printing and computer-aided design (CAD), are revolutionizing auto frame repair, enabling precise measurements and customized repairs. |

| Sustainability Focus | There is a growing emphasis on eco-friendly practices, with technicians adopting recyclable materials and efficient energy-based repair methods. |

The economic landscape surrounding auto frame repair is intricate and multifaceted:

Market Dynamics: The industry exhibits high competition, with independent workshops, dealership services, and specialized frame straightening facilities vying for customers. Market trends indicate a growing demand for specialized repairs due to complex vehicle designs.

Investment Patterns: Significant investments are directed towards research and development of advanced repair technologies, training programs, and equipment upgrades, reflecting the industry’s commitment to innovation.

Economic Impact: Auto frame repair contributes substantially to economic systems, supporting employment, generating revenue, and fostering local business growth. According to a recent study, this sector employs over 500,000 technicians globally.

Technological breakthroughs have revolutionized auto frame repair, opening new possibilities and enhancing efficiency:

Robotic Systems: The introduction of robotic arms in frame straightening has improved precision, reduced labor costs, and increased production speed. These systems are particularly valuable for repetitive tasks.

Computerized Analysis: Advanced software applications enable technicians to perform virtual simulations, predict stress patterns, and optimize repair strategies, leading to more effective solutions.

3D Scanning and Printing: 3D scanning technology captures detailed vehicle data, aiding in custom part design and rapid prototyping. 3D printing allows for the creation of intricate replacement parts, reducing lead times.

Regulatory frameworks play a crucial role in governing auto frame repair practices, ensuring safety standards and ethical business practices:

Safety Standards: Many countries have established stringent safety norms for vehicle structural integrity, including frame repairs. These standards dictate acceptable repair methods, materials, and quality control measures.

Environmental Regulations: Policies related to waste management and the use of eco-friendly materials guide industry practices, promoting sustainability in frame repair processes.

Licensing and Certification: Technicians and repair facilities often require licensing and certification to operate legally. This ensures a minimum level of proficiency and adherence to industry standards.

Despite its advancements, auto frame repair faces several challenges that require strategic solutions:

Skilled Labor Shortage: The demand for highly skilled technicians outstrips the available workforce, leading to labor shortages in many regions. Addressing this gap through training programs and educational initiatives is essential.

Costly Equipment: Advanced repair technologies can be expensive, posing financial challenges for smaller workshops. Governments and industry bodies can facilitate access to funding and grants to support equipment acquisition.

Customer Trust and Perception: Some consumers harbor misconceptions about the quality of frame repairs, often favoring OEM (Original Equipment Manufacturer) parts. Transparent marketing and educational campaigns can dispel these myths.

Case Study 1: Sustainable Frame Repair in Germany

A German auto repair chain pioneered an eco-friendly approach to frame repair, winning industry acclaim. They implemented a comprehensive recycling program for metal scrap generated during repairs, reducing environmental impact. Additionally, their use of electric welding equipment and energy-efficient facilities earned them a reputation for sustainability. This case highlights the potential for green initiatives in auto frame repair.

Case Study 2: Digital Transformation in Japan

Japanese auto manufacturers have led the way in digitalizing frame repair processes. A renowned automaker’s framework involves utilizing CAD software for precise measurements and virtual simulations, ensuring optimal repairs. Their integration of robotics has also reduced cycle times significantly. This case study demonstrates the power of digitalization in enhancing repair efficiency.

The future of auto frame repair is brimming with opportunities and emerging trends:

Autonomous Repair Technologies: The development of self-driving vehicles may lead to automated frame repair systems, revolutionizing the industry. These technologies could offer faster, more efficient repairs while reducing labor costs.

Advanced Materials Integration: As lightweight materials gain prominence, frame repair techniques will need to adapt accordingly. Newer composites and alloys require specialized handling, opening doors for innovative repair methods.

Global Standardization: Efforts to harmonize global safety standards could streamline the repair process, enabling technicians to work across borders with minimal training gaps.

Auto frame repair stands as a cornerstone of the automotive industry, ensuring vehicle safety and longevity. Its global impact, technological advancements, and continuous evolution highlight its significance. As the industry navigates challenges and embraces emerging trends, the future looks promising for this specialized field. By fostering innovation, addressing skills gaps, and promoting sustainable practices, auto frame repair will continue to play a pivotal role in shaping the automotive landscape.

Q: How do I know if my vehicle needs frame repair?

A: Signs of frame damage include uneven wheel alignment, visible deformities in body panels, or unusual noise during driving. A professional inspection is the best way to confirm if frame repair is required.

Q: Are there eco-friendly options for auto frame repair?

A: Absolutely! Many repair facilities now offer sustainable practices, such as recycling metal scrap, using eco-friendly cleaning solutions, and opting for energy-efficient equipment.

Q: Can I learn auto frame repair without formal training?

A: While it’s possible to pick up basic skills, formal training is highly recommended for specialized repairs. Many technical schools and online platforms provide comprehensive courses tailored to this trade.

Q: How often should I get my vehicle’s frame checked?

A: Regular frame inspections are not typically required unless you’ve been in an accident or experienced significant impact. However, annual checks can help identify minor issues early on.

Auto frame repair is a specialized service for restoring vehicle structural integrity post-accident……..

Auto frame repair is a critical service that restores damaged vehicle frames to their original align…….

Auto frame repair is essential for vehicles showing signs of structural damage, such as bends, warps…….

Auto frame repair is vital for vehicle safety and structural integrity after damage or accidents. Wh…….

Auto frame damage from accidents or disasters requires specialized repair. The process involves eval…….

Scams in auto frame repair target drivers, charging excessively for temporary fixes or submitting fa…….

Auto frame damage ranges from minor dents to severe structural issues, with expert assessment crucia…….

Auto frame damage ranges from minor to severe. Before deciding between repair or replacement, get a…….

Weather conditions, often overlooked, significantly impact vehicle structures, leading to a growing…….